If you are interested in using a photopolymer plate making lab which may be available in some printmaking departments or studios, this information will be valuable to you. While I describe the process that I use to make the plates, I'll inject a few interesting resources I've found on the web that document inexpensive ways to set up a plate-making operation in your own home, although I have no experience doing it in that fashion.

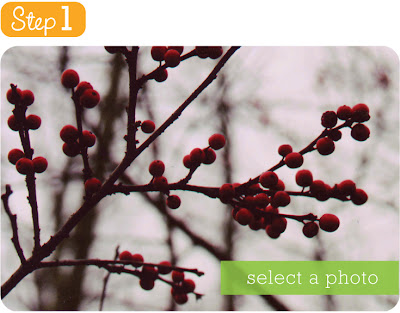

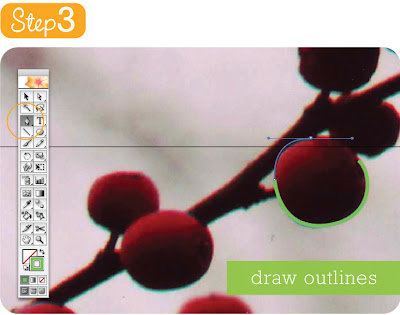

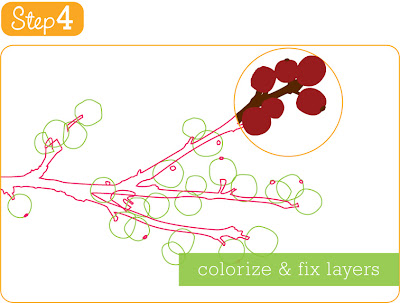

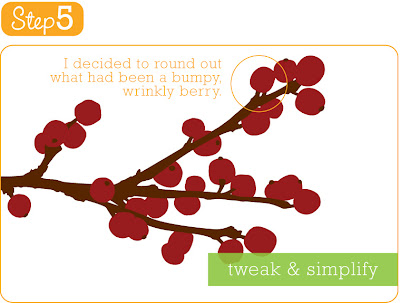

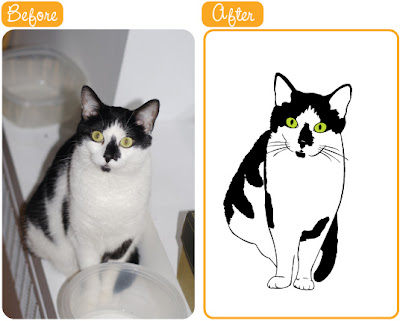

Step 1: At the end of the last installment we had separated the two colors but had left them in their appropriate Pantone colors. In this step we need to convert each colored portion into plain black. Remember that grays or halftones do not work well in this process, so make sure everything is either black or white.

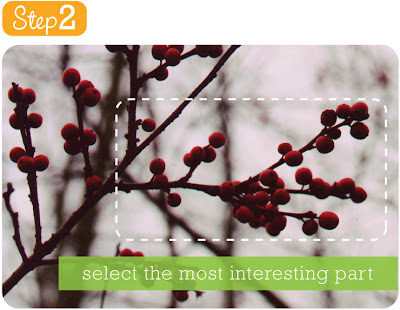

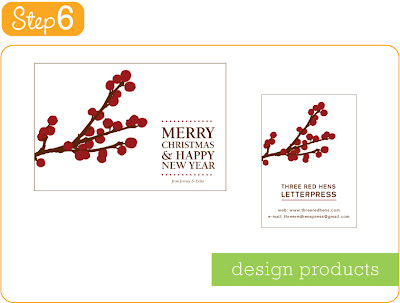

Step 2: Resize the images to be the same size as they will appear on your final letterpress product. If you'd like to use the same image in multiple sizes, you'll need to make multiple printouts and multiple plates. I've combined both images onto one 8.5"x11" page and printed a single copy. If you are interested in drawing something by hand with traditional pen & ink you can skip to this step in the process and use that illustration to make a negative directly.

Step 3: A negative needs to be made from your printout. Using a film negative service will produce a superior negative, but if you're doing it low budget or doing it at home, a transparency from a copy machine will work just fine. Load the transparencies into the copy machine and select "Negative/Positive" (may differ from machine to machine) and create a negative of your printout. Since transparencies are not quite as opaque as film negatives it's a good idea to make two copies, line them up exactly, and tape them together (being careful not to cover any of your art).

Step 4: This step needs to be done in a darkroom environment because the plates are light sensitive. If you decide to set up shop at home, you can purchase virgin plates from Boxcar Press in various sizes & widths. If necessary, cut a plate to fit the size of your negative – it can be smaller but make sure all your art is on top of the plate. All the photopolymer plates I've worked with have a side with a protective cover on it. Peel that off when you're ready and flip your negative face down on top of the freshly peeled side. Looking at it, your art should now be backwards.

Step 5: In order to "burn" your image onto the plate, you need to expose the plate to light. Thankfully I have access to a lab with a big expensive machine that has a vacuum action to pull the negative tightly against the plate and expose the plate to the light needed. With any machine or even in your own home if you don't have resources with recommended exposure times, you may have to do a little experimentation to get it just right. Exposure times can also differ depending on the weight of your lines or the intricacy of your design, I've found.

There's a DIY tutorial for making photopolymer plates in your own home by Maggie Bergman that I've found at Silver Clay Art. She details some of the above steps as well, but most importantly talks about how to clamp a negative to the plate using clips, expose using fluorescent or halogen lights, and how to make test strips. All very important things if you're interested in doing this at home.

Step 6: (This step should be done in a darkroom environment.) If you have a plate-washing machine you can use that (I do about 6 minutes this way), but if not use a soft brush and water to rub away the part of the plate that was not touched by light coming through your negative (aka the white space in your original). The plate will feel slimy (and be kind of smelly) during this process. You want to continue lightly scrubbing until the details of your design start to feel sharp-edged under your fingers. If there are little bumps in the middle of white space areas or the plate still feels really slimy, you need to scrub a little more. Don't scrub too vigorously or too long – you may end up with no design at all! Maggie Bergman recommends 2-3 minutes of scrubbing to get it cleaned out when doing it by hand. When you're all done you'll see what will be the colored part of your design raised in the plastic.

Step 7: (This step does not need to be done in the dark.) Before you use your plate it's important to firm it up. I use a little plate oven that's at about 80 degrees Celsius for 5-6 minutes, but Maggie Bergman recommends using a blow dryer or fan heater at home. I've seen someone somewhere talking about nail polish hardening machines, too. :-) You don't need to completely dry out the plate – it should still be flexible when you're done and not overheated. Sometimes over drying can warp thin lines or even make the plate start to split into layers.

Step 7: (This step does not need to be done in the dark.) Before you use your plate it's important to firm it up. I use a little plate oven that's at about 80 degrees Celsius for 5-6 minutes, but Maggie Bergman recommends using a blow dryer or fan heater at home. I've seen someone somewhere talking about nail polish hardening machines, too. :-) You don't need to completely dry out the plate – it should still be flexible when you're done and not overheated. Sometimes over drying can warp thin lines or even make the plate start to split into layers.

Step 8: This step is more of a precaution to make sure that all parts of the plate have been exposed by giving it a little more light.

.jpg)

_plates.jpg)

_plates.jpg)

_plates.jpg)

_plates.jpg)

_plates.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)